(c)iStock.com/sorbetto

- 93% of global product leaders say that predictive maintenance combined with real-time equipment monitoring enabled by integration is a must-have for factory planning today.

- 75% of global product leaders plan to implement factory of the future initiatives and programs in the next five years or less, starting with Industry 4.0

- 67% of automotive executives expect that new technologies enabled by real-time integration will enable their teams to reach and exceed lean management and continuous improvement goals starting this year and accelerating through 2030.

Boston Consulting Group’s recent article, The Factory of the Future provides insights into a recent global survey the consulting firm conducted of more than 750 manufacturing product leaders from leading companies in three industrial sectors: automotive (which includes suppliers and original equipment manufacturers, or OEMs), engineered products, and process industries.

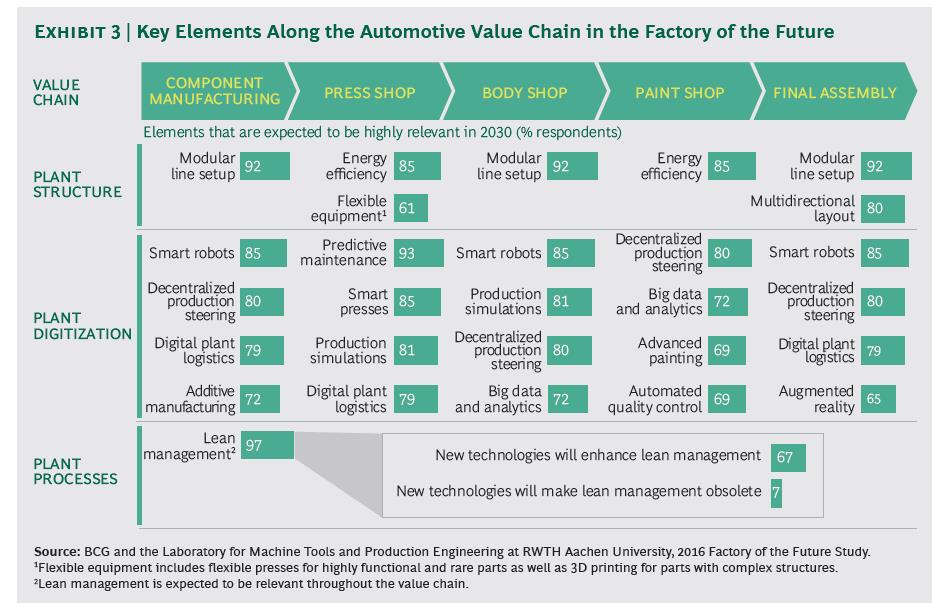

The survey’s objective is to define the vision for the factory of the future in 2030. Determining long-term benefits and the roadmap to implementation are also goals of the study Boston Consulting Group (BCG) and its research partner, the Laboratory for Machine Tools and Production Engineering at RWTH Aachen University, achieved. The Factory of the Future is a vision for how manufacturers should enhance production by making improvements in three dimensions: plant structure, plant digitisation, and plant processes.

Five ways integration fuels the factory of the future’s growth

Real-time integration based on intelligent objects that connect diverse enterprise systems including SAP, Salesforce and others is the foundation that manufacturing companies must adopt to excel in their Factory of the Future efforts. These real-time objects illustrate the future of Application Programmer Interfaces (API). APIs that will fuel and drive the Factory of the Future will enrich each real-time integration points across manufacturing networks. Intelligent Objects pervasively used today are the precursors to the most valuable APIs that will enable Factories of the Future tomorrow. With APIs continually improving and gaining the capability to provide insight and intelligence, the essential role of real-time integration in all factories of the future becomes clear.

The following are the five ways integration is enabling the Factory of the Future today:

Real-time integration enables the value chains supporting the Factories of the Future to continually accelerate, excel and improve with additional insight that drives future growth strategies. Bringing greater intelligence into each integration point across the value chains supporting the Factories of the Future leads to new technologies delivering greater lean management benefits. Real-time integration will deliver strong benefits in the areas of lean management, predictive maintenance, modular line setups, and the orchestration and collaboration of smart robots.

The Implementation Roadmap for the Factory of the Future shows how critical real-time integration is to the Factory of the Future’s vision being attained. Multidirectional layouts, modular line setups, sustainable production, the orchestration of smart and collaborative robotics and attainment of big data and analytics plans all are dependent on real-time integration. The following graphic from the study illustrates just how central integration is to the optimizing of plant structure and plant digitisation.

By integrating large-scale enterprise systems including those from SAP, Salesforce and others with legacy, 3rd party and homegrown systems, every area of production quality will improve. The most urgent need global manufacturers have is finding new ways to improve product, process and service quality without raising costs. Improving the quality of these three dimensions makes any manufacturer more trusted and successful in selling next-generation products. By aggregating data using real-time integration so that big data and advanced analytics can be used to find new patterns, some of the world’s most well-known manufacturers are excelling on product quality. To produce cylinder heads at its plant in Untertürkheim, Germany, Mercedes-Benz uses predictive analytics to examine more than 600 parameters that influence quality. Mercedes-Benz is an early adopter of using Big Data and advanced analytics to improve quality management and bring high precision to engineering. Bosch has implemented software that analyzes data about its production of fuel injectors in real time. The software monitors process adherence and recognises trends. It automatically transmits information about deviations to operators, allowing them to improve the process accordingly.

Real-time integration across and within manufacturing systems enables multi-directional layouts of production workflows. The Audi R8 manufacturing facility in Heilbronn, Germany, does not have a fixed conveyor so the teams there has greater multidirectional flexibility in building customised vehicles. Real-time integration across the Audi factory floor is essential to provide R8 production teams with the specifics of how they can best collaborate and deliver the highest quality vehicles in the shortest amount of time. Real-time integration is enabling driverless transport systems, guided by a laser scanner and radio frequency identification technology in the floor, which moves the car bodies through the assembly process. These systems enable assembly layout changes quickly with no impact on existing production. Enabling real-time integration often involves extensive field mapping between different systems, which is a lengthy and error-prone process. Integration technology provider enosiX has developed a unique, real-time integration technology that obsoletes the need for field mapping and supports bi-directional data updates.

Enabling the Factory of the Future’s production operations to flex in response to rapidly changing customer requirements is entirely dependent on real-time, reliable integration of production and customer-facing systems. The implications of the study on the future of manufacturing underscore just how critical it is for manufacturers to be agile enough to create entirely new business models while gaining insight and intelligence into how they can continually improve lean manufacturing. When real-time integration unifies a value chain for any manufacturer, their speed, scale and ability to simplify the complex processes required to serve customers turns into a formidable competitive advantage.