(c)iStock.com/.shock

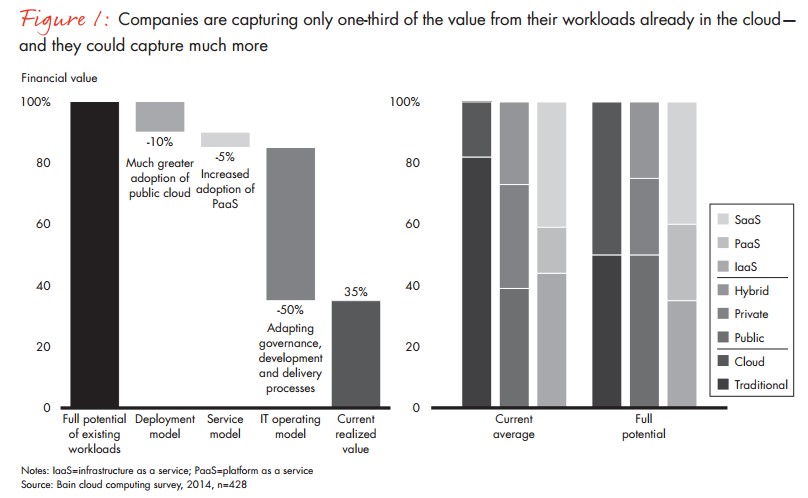

Enterprises are only realizing 35% of the total potential value of their cloud deployments according to a recent Bain & Company study. Companies that moved development to IaaS and PaaS clouds from Amazon Web Services (AWS) reduced downtime by 72% and improved application availability by 3.9 hours per user per year.

These and other key takeaways are from the recent Bain & Company study, Tapping Cloud’s Full Potential. The full report PDF is available for download here (free, no opt-in). The following graphic from the report illustrates the currently realized value of cloud deployments in enterprises today according to Bain & Company.

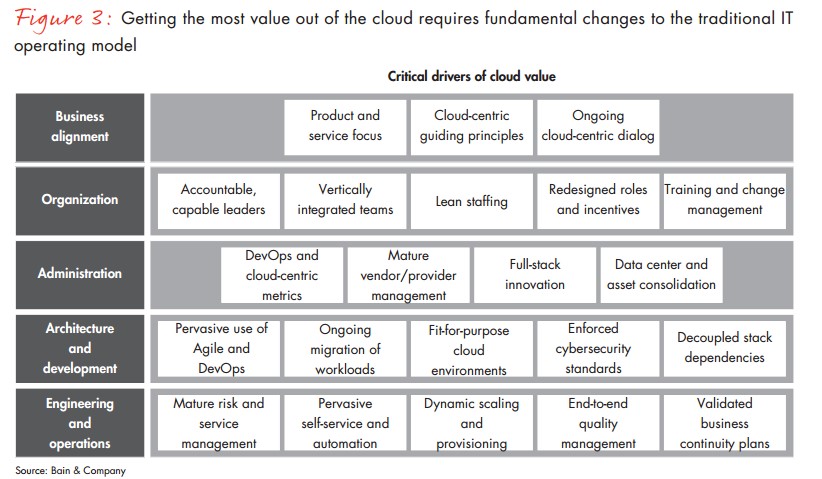

The researchers found several critical drivers of cloud value with one of the most important being the strengthening and clarifying of a product and service focus. The following graphic illustrates the critical drivers of cloud value.

Cloud Service Providers Give Manufacturers The Ability To Stay Competitive

Cloud-first strategies designed to accelerate and strengthen shifts in emerging business models is paying off according to Bain’s research results.

Manufacturers choosing to pursue a cloud-first strategy are focusing on evolving their business models, processes, systems and performance quickly to stay in step with customers’ needs. For many manufacturers, their customers’ pace is faster than internal IT organizations can anticipate and react to. Cloud Service Providers are helping to close that gap.

Here are five ways CSPs are making manufacturers more competitive:

- Bringing industry expertise to the shop floor level. The best CSPs serving manufacturers today have management teams that have decades of combined manufacturing experience in specific industries. The CEO of a specialty tools manufacturer remarked that his company’s cloud strategy was more focused on accelerating plant floor performance first. Working with a CSP that had expertise in their industry, this manufacturer was able to gain greater supply chain visibility and improve forecast accuracy, all with cloud-based apps.

- Solving legacy and third party system integration problems so that cloud-based ERP, CRM, supply chain management (SCM) systems can scale quickly. When a rust-belt based manufacturer of heating, ventilation and air conditioning (HVAC) systems had the opportunity to grow their business by expanding into build-to-order customized products, their CSP partner made it possible to integrate an entirely new product configurator and cloud-based ERP system module to manage quote-to-cash. Today, 30% of corporate-wide profits are from build-to-order selling strategies.

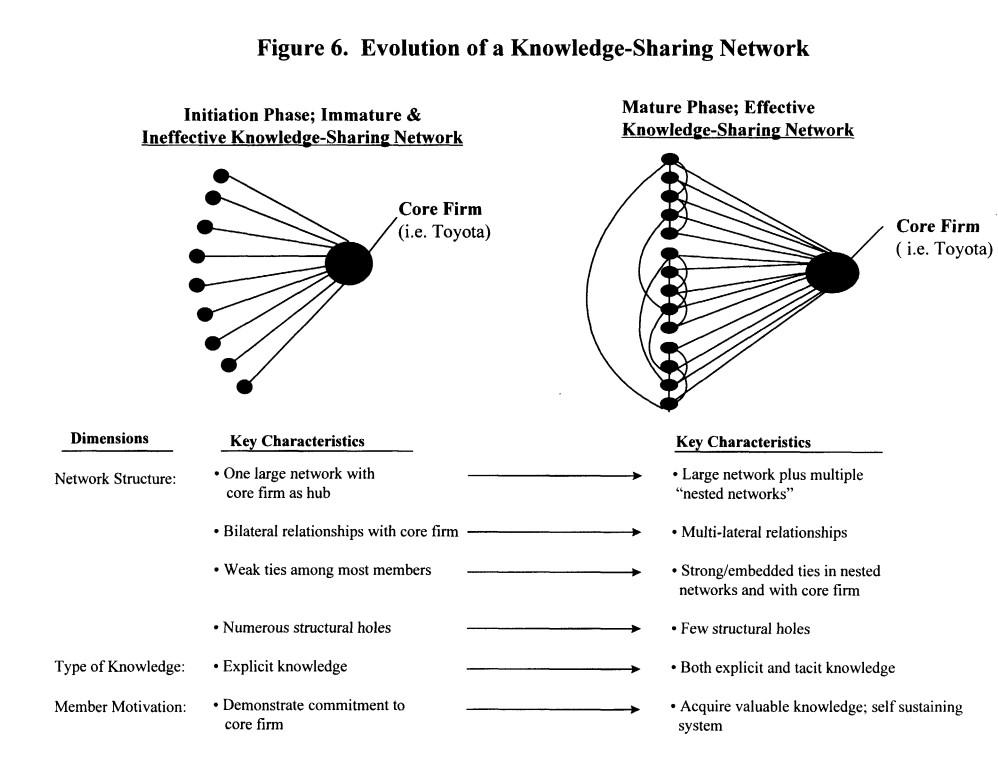

- Knowledge-sharing supplier networks are becoming more attainable for manufacturers thanks to cloud technologies and CSPs. All manufacturers have strategic plans that include greater integration of their supplier networks, with many seeking to create knowledge-sharing networks. One of the best studies of how to create a knowledge-sharing network is from Dr. Jeffrey Dyer and Dr. Kentaro Nobeoka based on their intensive work with Toyota. Their study, Creating And Managing A High Performance Knowledge-Sharing Network: The Toyota Case is a great read. The following graphic from the study illustrates the evolution of a knowledge-sharing network. Manufacturers are relying on cloud platforms and CSPs to enable shifts in network structures and nurture change management to create self-sustaining systems.

- Two-tier ERP adoption in manufacturing is growing as CSPs master cloud ERP systems. CSPs are moving beyond providing basic services, specializing in cloud ERP, CRM, SCM, pricing, services and legacy system integration to keep pace with manufacturers’ demands. In one high tech manufacturer, their CSP partner orchestrated the procuring and launch of their cloud-based two-tier ERP system integrated to an SAP instance in their headquarters. Today they operate production centers in Asia, North America and Australia, all coordinated through the main SAP instance in the U.S. headquarters.

- Making service level agreements (SLAs) more relevant to manufacturing business models. Instead of just getting SLAs for uptime, security and system stability, manufacturers are getting advanced manufacturing intelligence dashboards that provide visibility to the plant or production center level.

Bottom Line: Manufacturers are increasingly relying on CSPs’ cloud, industry and integration expertise to support the transition many are making to new business models and get greater than 35% of the value from their cloud investments.